A wafer check valve is a form of device that utilizes a disc-molded component to regulate the movement of fluid through it. The disc is put in the middle of the valve body and rests on two seats, one on either side of the control device. If the liquid stress is applied, the disc needs against among the chairs and opens the valve. Once the pressure is introduced, the disc returns to its unique situation and closes the device.

Wafer Verify Valves: Understand The Doing work Mechanism

The operation of your wafer check valve is simple. When water strain is applied, it factors the disc against one of many car seats and opens the device. The disc profits to the preliminary placement and closes the control device the moment the stress is unveiled. Such a thing happens very quickly, so there is no postpone in stream.

Some great benefits of using a Wafer Check Valve

There are many advantages to employing a wafer check valve:

●They are very swift to close and open, so there is no hold off in circulation.

●They can be lightweight and straightforward to set up.

●They may be dependable and lengthy-sustained.

●They could be used in a number of applications.

●They are easy to keep.

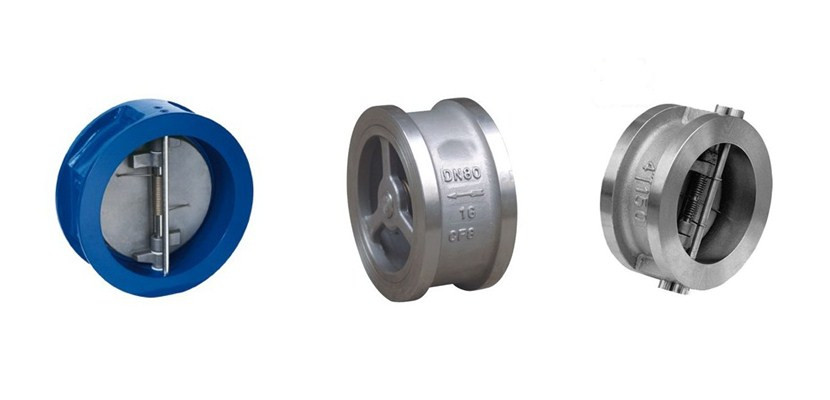

Types of Wafer Check out Valves

There are several varieties of wafer check valves offered:

●Single chair valves: These sorts of valves utilize a one disc to control stream. They may be simple and easy to use yet not as reputable as other wafer examine valves.

●Increase seat valves: These types of valves use two discs to control stream. They can be a lot more reliable than individual-seating valves but call for more room for installment.

Applications for a Wafer Check Valve

Wafer check out valves can be used in many different apps, including:

●Plumbing systems

●HVAC solutions

●Water remedy plants and flowers

●Moving stations

Installing and Maintenance Tips for a Wafer Check Valve

When putting in or keeping a wafer check valve, keep these pointers in mind:

●Make sure that the control device is properly aligned with all the piping before installation.

●Check out any spills after installation.

●Make sure that the discs are clean and free of dirt before functioning.

The best way to solve popular troubles:

Wafer verify valves are an essential crash-secure in several industrial apps. When mounted effectively, they guide to stop backflow and make certain that beverages and gas flow in the proper route.

●Even so, wafer verify valves can sometimes turn out to be trapped or fail to shut properly. This can be the result of a build-up of particles or a modification of pressure differential.

●In order to keep your wafer check valve in working order, you should regularly clean and check out the control device.

●When you notice any problems, you ought to talk to a competent technician for help.

If you take these simple steps, you can help to ensure that your wafer check valve will offer numerous years of reliable service.

Endnote:

We certainly have mentioned the many benefits of using a wafer check valve in a variety of applications. Additionally, it highlights how the wafer check valve is an easy, reliable, and simple-to-use choice for managing the flow of essential fluids.